We help your business with

Precision Aerospace CNC Machining Solutions Tailored to Your Engineering Challenges

Driven by firsthand experience, we deliver unparalleled machining solutions for businesses that need:

- Rapid Project Execution

- Proactive Problem Solving

- Reliability and Precision Everytime

Precision Aerospace CNC Machining Services

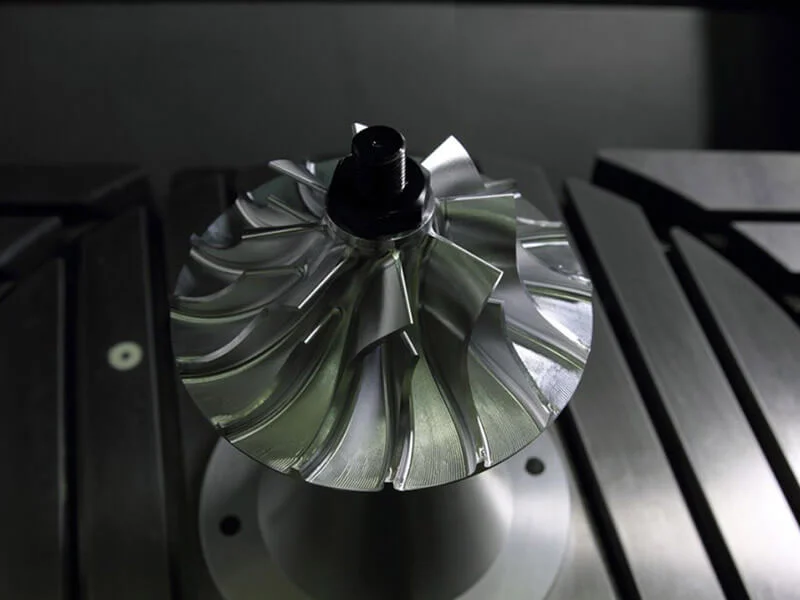

At OAK Engineering & Manufacturing, we combine state-of-the-art CNC machining with advanced composite fabrication to deliver mission-critical parts for the aerospace industry. Our engineers hold tight tolerances and surface finishes, ensuring every component meets the highest quality and performance standards.

Aerospace-Grade Custom Parts Fabrication

At OAK Engineering and Manufacturing, we pride ourselves on our versatile CNC machining and composite capabilities. Our state-of-the-art facility works with a wide array of metals, resin systems and fiber reinforcements, ensuring we can meet diverse client needs.

- Carbon Fiber

- Kevlar

- Fiberglass

- Paints – Primer

- Top coats / Anti-static coatings

- Epoxy and Polyurethane

- Teflon

- Composite Tubes and Rods

Precision Aerospace CNC Machining Capabilities

At Oak Engineering & Manufacturing, we marry state-of-the-art CNC machining with advanced composite fabrication to deliver mission-critical aerospace components.

Our process expertise includes:

- 3-axis milling

- 4-axis milling

- 5-axis milling

- CNC turning

If your parts exceed our standard size or tolerance guidelines, simply request a custom quote—our engineers will tailor the optimal manufacturing solution to your exact specifications.

CNC Machining Tolerance

Selecting the right tolerance for your part is critical for its use and to control costs. The higher the tolerance the better the part but the more costly. We can help you choose the right balance of precision to cost.

Maximum Part Size

Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). Lathe parts up to 62” (1,575 mm) length and 32” (813 mm) diameter.

General Tolerance

Tolerances on metals will be held to +/- 0.005″ (+/- 0.127 mm). Plastics and composites will be +/- 0.010”.

Precision Tolerance

We can manufacture and inspect to tight tolerances, including sub +/- 0.001″ tolerances.

Threads and Tapped Holes

We can accommodate any standard thread size.

Edge Condition

Sharp edges are broken and deburred by default

Surface Finish

The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified during the quoting process.

Our Process is what makes the difference

01

Understanding your projects

We start by thoroughly understanding your project’s requirements, ensuring we capture every detail to deliver the perfect part tailored to your specific needs.

02

Ensuring Manufacturability

We will review your designs thoroughly, ensuring every custom part is manufacturable, optimizing efficiency, and minimizing costly errors.

03

production

plan

We create a detailed production plan and timeline, outlining each step to ensure efficient, timely, and precise manufacturing of your custom parts.

04

Final part production

We proceed with the final production, followed by careful packaging to ensure your parts arrive in perfect condition, ready for immediate use.

Industries We Serve

Explore our offerings in custom composite manufacturing for diverse industries. From aerospace to medical, we create solutions that cater to specific needs with precision and care.

Aerospace & Aviation

Delivering advanced custom machining solutions for the aerospace sector, ensuring safety, efficiency, and innovation.

Medical Solutions

Providing custom machining solutions for the medical sector, focused on precision, durability, and patient safety.

Marine Applications

Creating resilient composite materials suited for the marine industry, designed to withstand harsh conditions.

Sporting Goods

Offering advanced composite solutions for the sporting industry, prioritizing strength, performance, and innovation

Automotive Solutions

Providing custom parts that enhance performance.

*We do not take single part projects

Industrial Products

Providing durable parts that enhance performance and ensure long-lasting reliability under any condition.

Need Help Getting Your Parts Just Right?

Our team of first-hand engineers are committed to your part’s perfection.

Engineers dedicated to your project’s success, providing hands-on assistance and expert advice to ensure your custom parts are perfect from start to finish.

FAQ

Our team is ready to help you with any question

What CNC machining processes does Oak Engineering & Manufacturing offer for aerospace components?

We provide 3-, 4-, and 5-axis CNC milling; precision CNC turning and specialized drilling and tapping. Our multi-axis centers and high-speed spindles let us tackle everything from simple brackets to complex turbomachinery parts.

Which aerospace-grade materials can you machine?

We routinely work with aluminum alloys, titanium, stainless and tool steels, and other nickel-based superalloys, plus high-performance plastics. If you need another alloy, just ask—we’ll source it for your project.

What tolerances and surface finishes can Oak Engineering achieve?

Standard tolerances are ±0.002″ (±0.05 mm); in many cases we can hold ±0.005″ (±0.12 mm). Surface finishes down to 125 Ra or better. Post-machining treatments are also available to meet your spec.

What are your maximum part-size limits and production capacities?

We handle both one-off prototypes and high-volume runs—our flexible cell layout lets us scale quickly to meet batch sizes from single pieces to thousands.

How do I request a quote for aerospace CNC machining?

Simply send us your 3D CAD file (STEP or IGES), material spec, quantity, and any special tolerances or surface treatments. You can upload everything through our online quote form or email it to sales@oakengineering.com—our team will respond with a detailed estimate within one business day.

Let's talk, we are ready to help you get the perfect part.

Our team is ready to help you with all your needs.