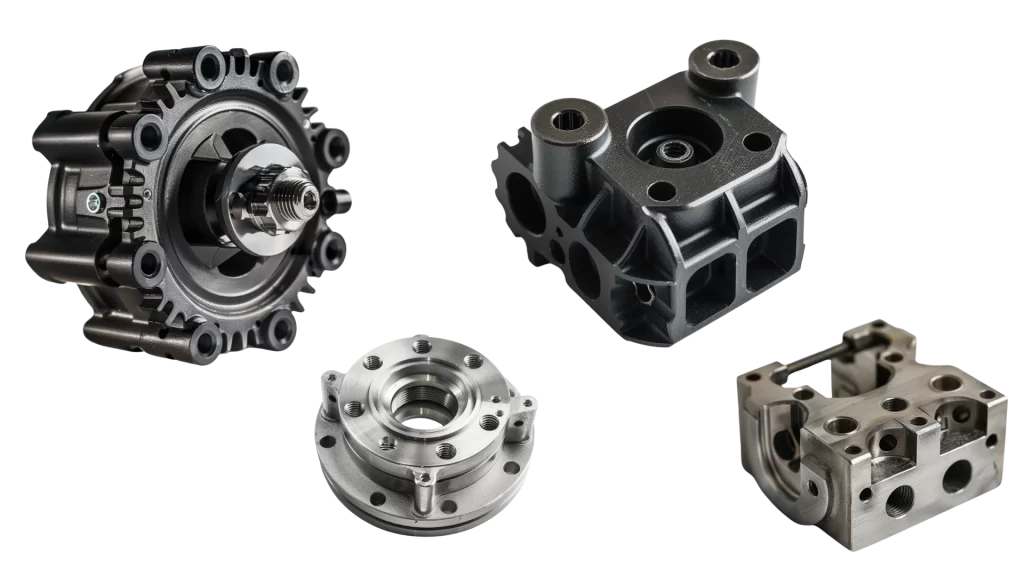

CNC Machining Services

We bring your designs to reality

Driven by firsthand experience, we deliver unparalleled CNC prototyping and manufacturing.

- Reliability and Precision Everytime

- Proactive Problem Solving

- Rapid Project Execution

For Engineers from Engineers

with Precision & Efficiency in Every Part

At Oak E&M, we understand the challenges you face in designing, prototyping, and manufacturing components because we’ve been there. Our team of experienced engineers come from OEM’s and End-Users who have constantly had to manage vendors and subcontractors.

We know your pain.

That’s why we founded Oak E&M, to create high-quality precise parts that save you time and money.

Our team of experts engineers are ready to help you

Get Your Custom Quote in 24 Hours

Reviewed by a real-life experienced engineers

Enter details, upload your file and specify your needs.

Get a custom quote in 24 hours.

Ideal for large orders or orders with special needs.

Contact an Engineer

Our Team of Engineers are ready to help you

Need a one-on-one engineer support

to get your part just right before manufacturing.

Contact Us Now!

Our Process is what makes the difference

01

Understanding your projects

We start by thoroughly understanding your project’s requirements, ensuring we capture every detail to deliver the perfect part tailored to your specific needs.

02

Ensuring Manufacturability

We will review your designs thoroughly, ensuring every custom part is manufacturable, optimizing efficiency, and minimizing costly errors.

03

production

plan

We create a detailed production plan and timeline, outlining each step to ensure efficient, timely, and precise manufacturing of your custom parts.

04

Final part production

We proceed with the final production, followed by careful packaging to ensure your parts arrive in perfect condition, ready for immediate use.

Need Help Getting Your Parts Just Right?

Our team of first-hand engineers are committed to your part’s perfection.

Engineers dedicated to your project’s success, providing hands-on assistance and expert advice to ensure your custom parts are perfect from start to finish.

CNC Machining Materials

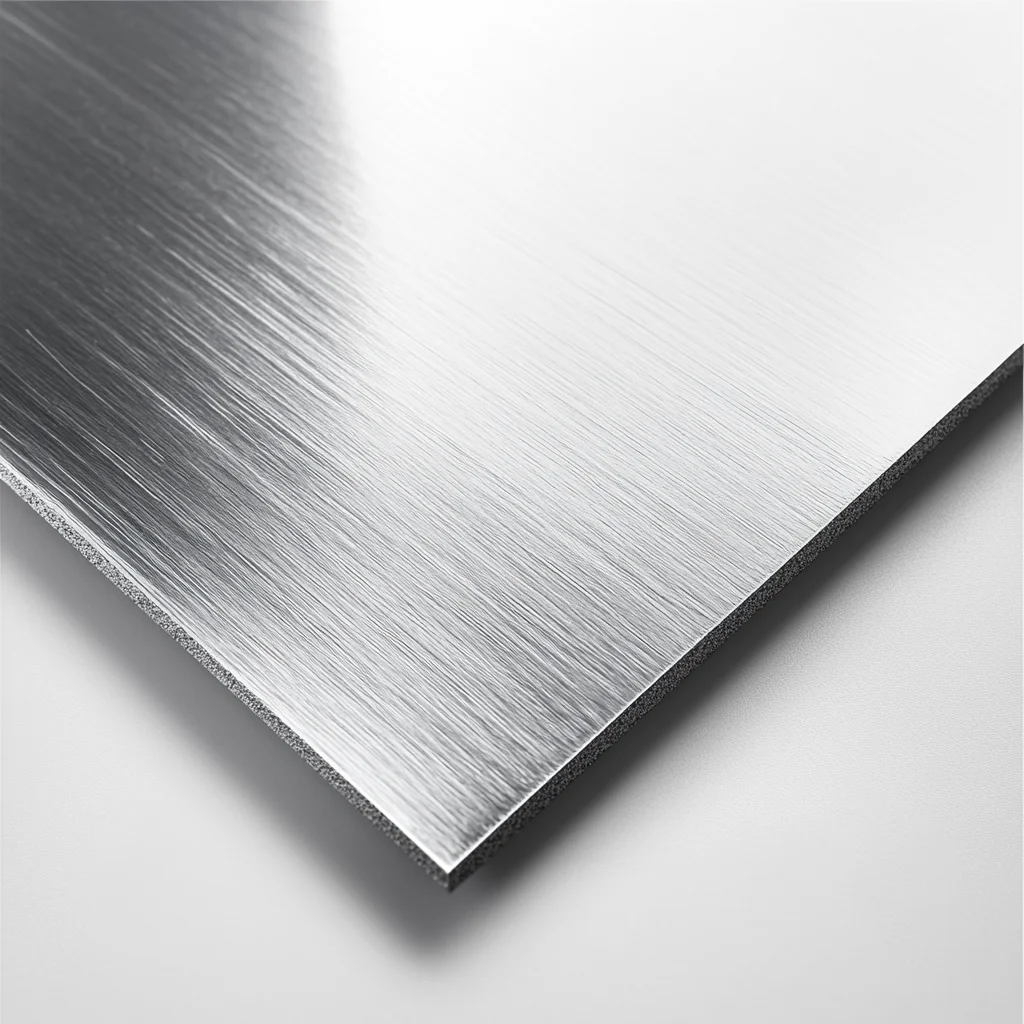

Aluminum

Aluminum is ideal for CNC machining due to its strength, light weight, and corrosion resistance. It’s easy to machine, allowing for precise, complex parts with excellent finishes. Perfect for aerospace, automotive, and electronics industries, aluminum parts are durable yet lightweight. It’s great for heat dissipation and cost-effective for both prototypes and mass production.

Avaliable CNC Machining Aluminum Alloys:

- 6061 (General-purpose)

- 2024 (Aerospace grade)

- 7075 (High-strength aerospace and military)

- 5052 (Marine-grade, corrosion-resistant)

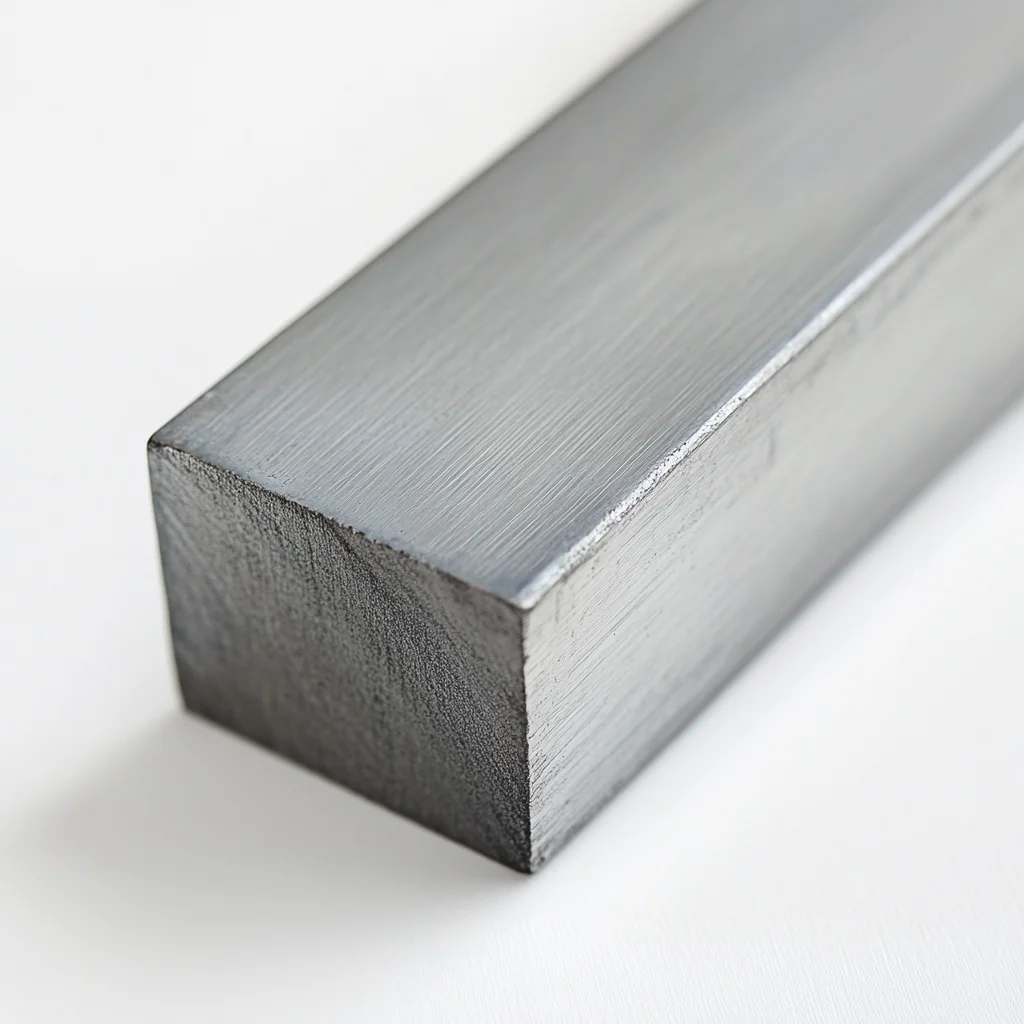

Steel

Steel is a go-to material for CNC machining, offering exceptional strength and durability. It’s suitable for high-stress applications and heavy-duty parts. Steel’s versatility makes it ideal for various industries, including construction, automotive, and manufacturing. While harder to machine than aluminum, steel provides superior wear resistance and load-bearing capabilities.

Avaliable CNC Machining Steel Alloys:

- A36/1008 (General structural steel)

- 4130 (Chrome-moly alloy steel)

- 1075 (High-carbon steel)

- AR400 (Abrasion-resistant steel)

- A2 (Tool steel for hardening)

Stainless Steel

Stainless steel excels in corrosion resistance and aesthetic appeal. It’s perfect for parts exposed to harsh environments or chemicals. CNC machined stainless steel components are widely used in medical devices, food processing equipment, and marine applications. While more challenging to machine, it offers excellent strength-to-weight ratio and long-lasting performance.

Avaliable CNC Machining Stainless Steel Alloys:

- 303 (Free-machining stainless)

- 305 (Austenitic stainless)

- 316 (Marine-grade stainless)

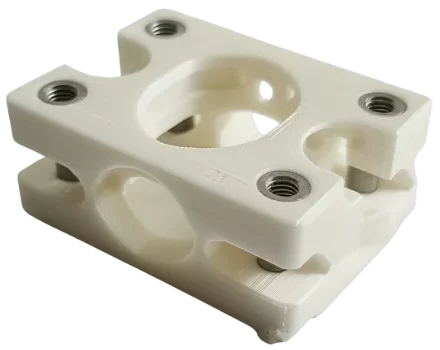

Plastics

Plastics offer lightweight, cost-effective solutions for CNC machining. They’re easily machinable, allowing for complex geometries and tight tolerances. Ideal for prototypes, electrical insulators, and low-friction components. Different plastics provide various properties like chemical resistance, thermal insulation, or optical clarity, suiting diverse applications in electronics, automotive, and consumer goods.

Avaliable CNC Machining Plastics Alloys:

- Teflon (PTFE, low friction)

- Delrin (POM, high strength)

- Acrylic (PMMA, optical clarity)

- ABS (Impact-resistant)

Brass

Brass is valued in CNC machining for its excellent machinability and attractive golden appearance. It’s corrosion-resistant and conducts heat well, making it ideal for plumbing fixtures, electrical components, and decorative parts. Brass is often chosen for its antimicrobial properties, making it suitable for applications in healthcare and public spaces.

Copper

Copper’s outstanding electrical and thermal conductivity make it crucial for CNC machined components in electronics and heat management systems. It’s also prized for its corrosion resistance and antimicrobial properties. While softer than many metals, copper’s malleability allows for intricate designs in electrical connectors, heat sinks, and artistic applications.

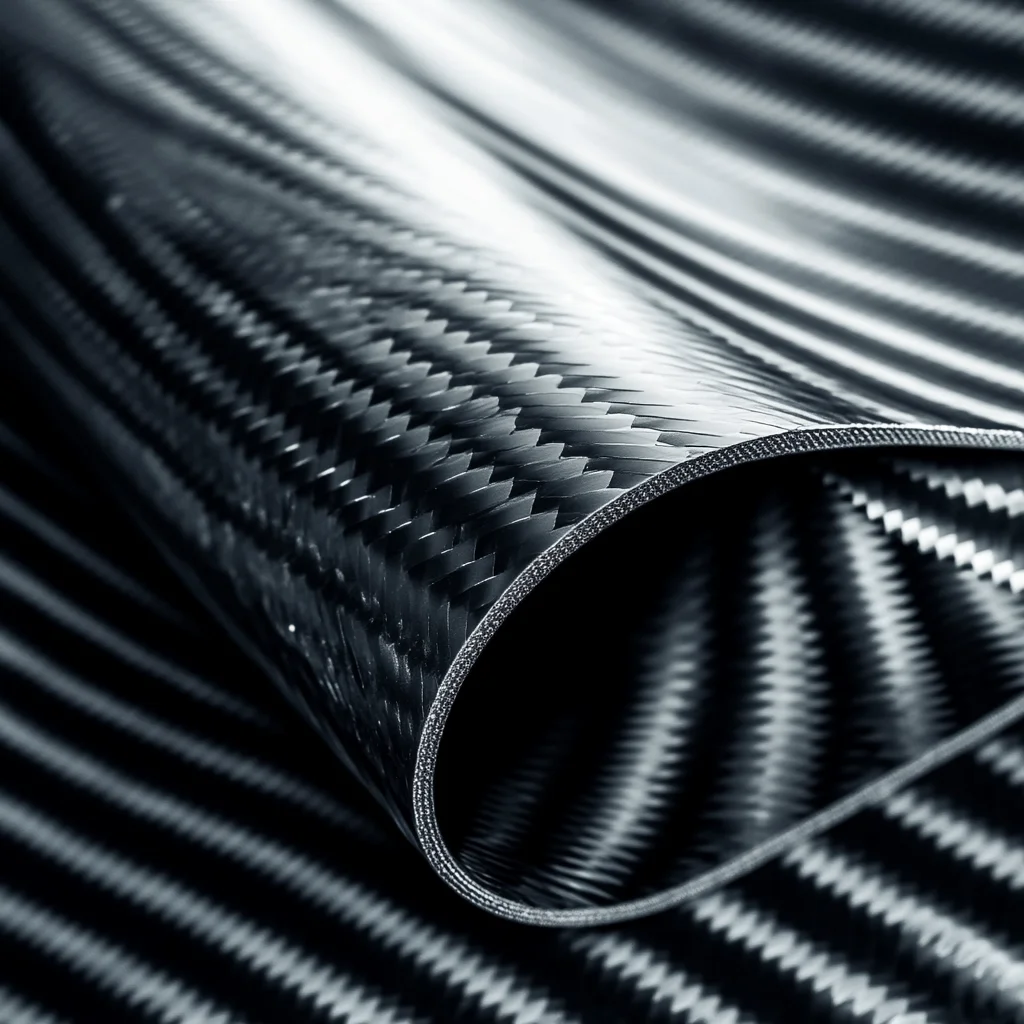

Composites

Composite materials combine the best properties of different substances, offering unique advantages in CNC machining. They typically provide high strength-to-weight ratios, excellent dimensional stability, and specialized characteristics like electrical insulation or heat resistance. Ideal for aerospace, electronics, and high-performance applications where weight reduction and specific material properties are crucial.

Types of Composite Materials:

- Garolite (Fiberglass-reinforced epoxy laminate)

- FR4 (Flame-retardant fiberglass epoxy)

- Carbon Fiber (High-strength, lightweight)

- Fiberglass (Strong, insulating)

Titanium

Titanium is prized in CNC machining for its exceptional strength-to-weight ratio and biocompatibility. It’s corrosion-resistant and maintains strength at high temperatures, making it ideal for aerospace, medical implants, and high-performance automotive parts. While challenging to machine, titanium components offer unmatched durability and performance in demanding environments.

Rubber

CNC machining rubber provides precise, custom components with unique elastomeric properties. Ideal for seals, gaskets, and vibration dampeners, machined rubber parts offer excellent compression set resistance and can be tailored to specific hardness requirements. This versatile material is crucial in automotive, aerospace, and industrial applications where flexibility and sealing are paramount.

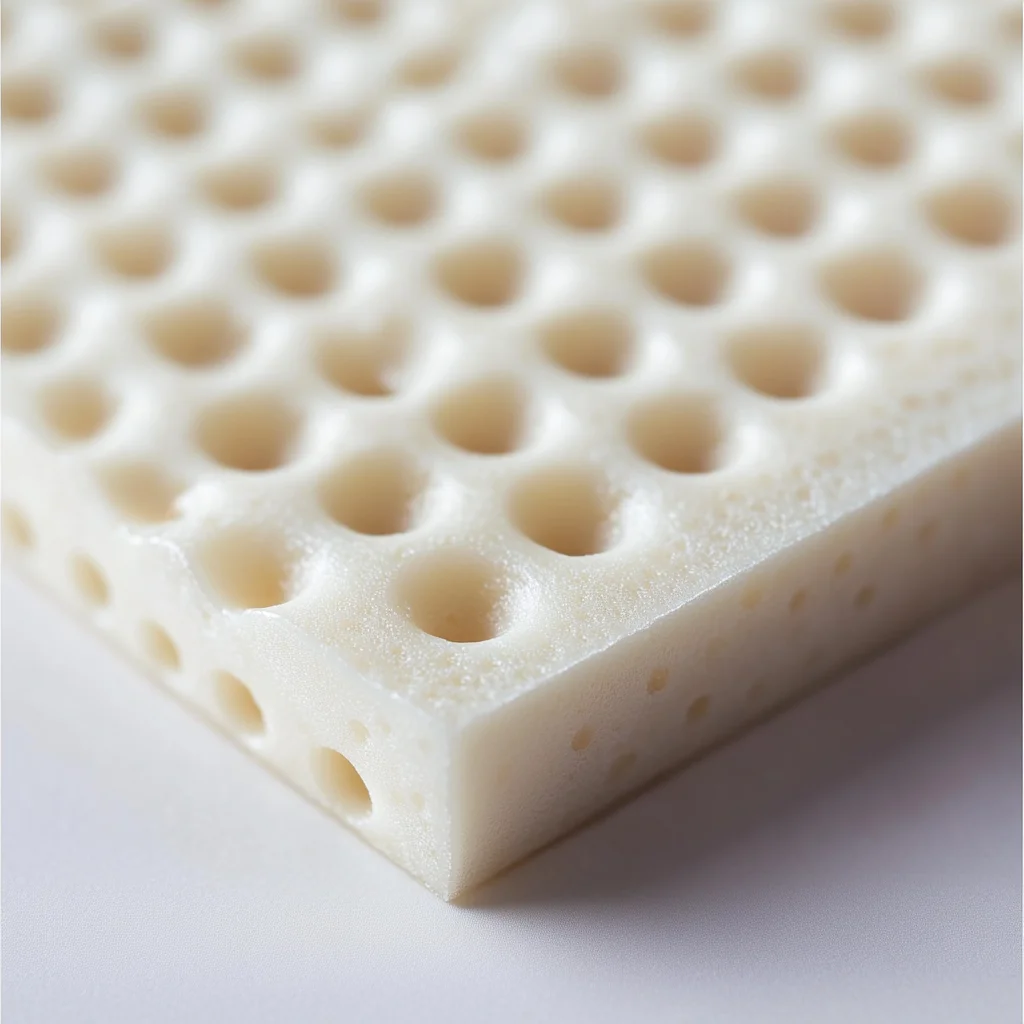

Foam

CNC machined foam offers lightweight, cushioning solutions with precise dimensions and contours. It’s ideal for packaging, insulation, and prototyping applications. Different foam types provide various densities and properties, allowing for customized shock absorption, thermal insulation, or acoustic dampening. Foam machining is crucial in aerospace, automotive, and consumer product industries.

Super-Alloys

Super-alloys are high-performance materials designed for extreme conditions. CNC machined super-alloy components offer exceptional strength, corrosion resistance, and stability at high temperatures. These materials are crucial in aerospace, gas turbines, and chemical processing industries where standard metals would fail. While challenging to machine, super-alloys provide unparalleled performance in the most demanding environments.

Starting a project and need helping getting your part just right?

Let’s talk, we are ready to help you get the perfect part.

FAQ

Our team is ready to help you with any question

Can you produce both prototypes and large production runs?

Yes, we offer services for both prototyping and production runs. Our CNC machines are well-suited for creating one-off prototypes, small batch productions, and large-scale manufacturing runs. We’ll work with you to determine the most cost-effective approach based on your quantity needs.

Do you offer engineering and design assistance or only machining services?

Yes, our main expertise is in developing and designing parts and bringing products to market. We are experts in unmanned vehicles development and composite parts production. Our team can take your concept from initial design through to final production, leveraging our deep experience in these specialized fields. We offer comprehensive design services, prototyping, and can guide you through the entire product development lifecycle.

How accurate are your CNC machining processes?

Our state-of-the-art CNC machines are capable of achieving very high precision, typically with tolerances as tight as ±0.001 inches (0.025 mm) for most materials. For projects requiring even tighter tolerances, we can often accommodate these needs – please discuss your specific requirements with our team.

How do I upload my design files for a custom quote?

You can upload your design files directly through our website’s quote request form. Accepted file formats include STEP | STP | SLDPRT | STL | DXF | IPT | X_T | X_B | 3DXML | CATPART | PRT | SAT | 3MF | JT files. Our team will handle the rest.

What industries do you serve with your custom manufacturing services?

We serve a wide range of industries including automotive, aerospace, medical devices, oil and gas industry, consumer electronics, and industrial equipment. Our custom manufacturing services are adaptable to meet the needs of various sectors.

How do you ensure the precision and accuracy of custom CNC manufactured parts?

We utilize advanced manufacturing technologies and precision equipment to ensure the highest levels of accuracy. Additionally, our experienced engineers and quality control team rigorously inspect each part to ensure it meets your exact specifications.