Composite Parts Production

Cutting-Edge Composite Engineering for Your Most Complex Challenges

Combining expertise and innovation to deliver precision-driven composite solutions, from prototype to production.

Streamlined composite production process for faster time-to-market

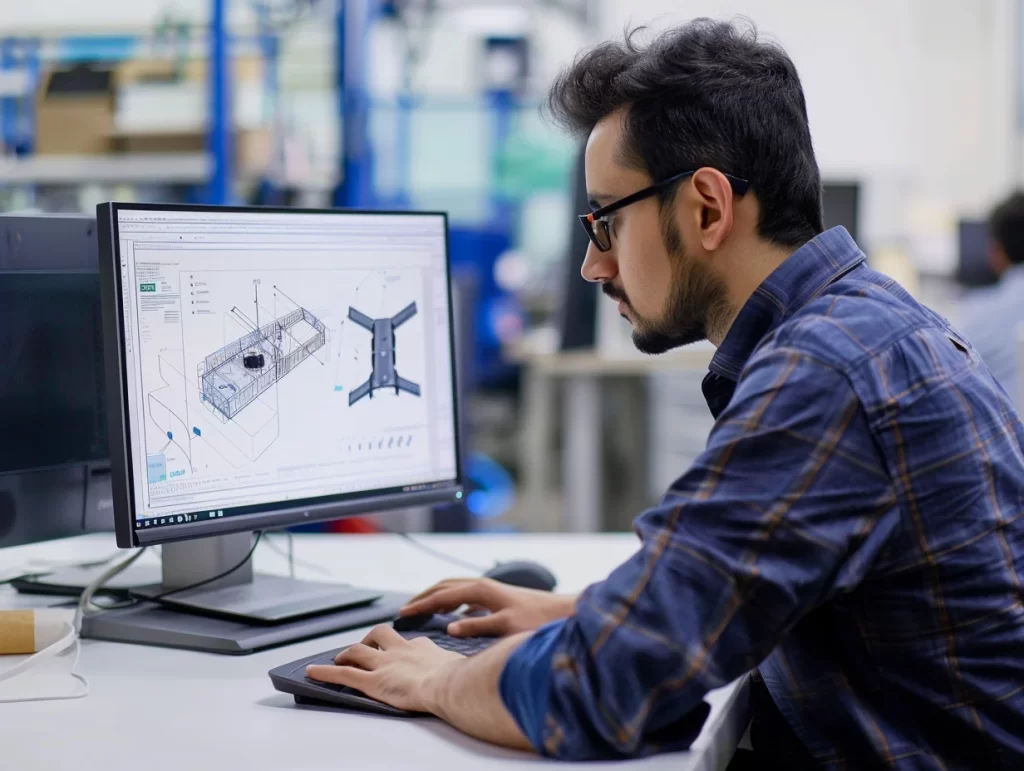

At OAK Engineering and Manufacturing, we’ve refined our composite production process to ensure efficiency without compromising quality. Our streamlined approach accelerates your product development cycle, getting your innovations to market faster. We integrate cutting-edge technology with our team’s extensive expertise to optimize every stage of production, from initial concept to final delivery.

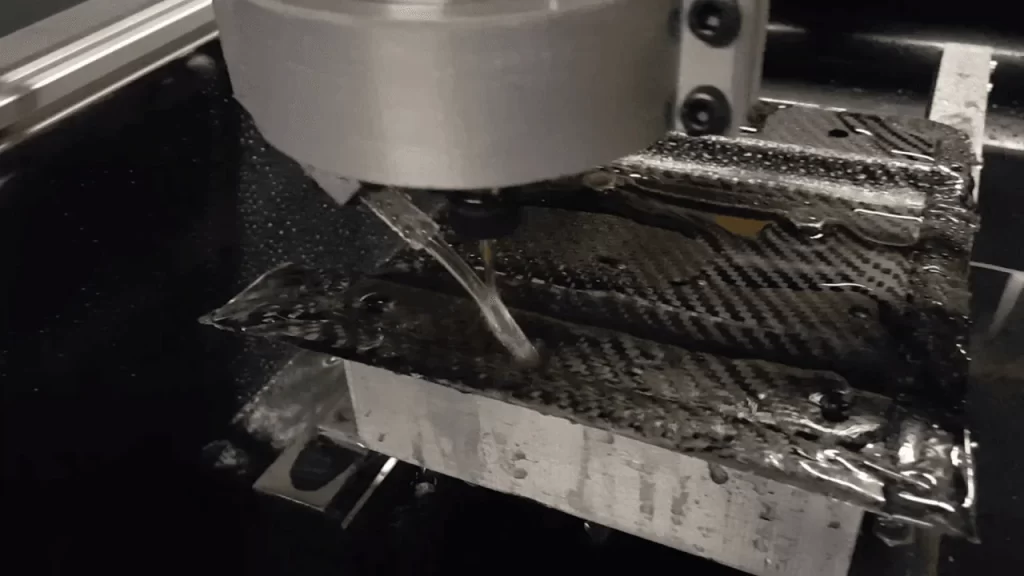

Tooling and Molding Production

Our tooling and molding production phase sets the foundation for your composite part's success. We employ advanced CAD/CAM systems and CNC machining to create precise, durable molds that ensure consistency across production runs.

Prototyping, Testing and controls

Our comprehensive prototyping, testing, and control processes ensure your composite parts meet or exceed performance expectations before full-scale production begins.

Production and Post Finishing

Once your design is validated, we transition seamlessly into full-scale production. Our advanced manufacturing facilities and skilled technicians ensure consistent, high-quality output, whether you need a small batch or large production run.

Materials Availables for Composites

At OAK Engineering and Manufacturing, we pride ourselves on our versatile composite capabilities. Our state-of-the-art facility works with a wide array of fiber reinforcements and resin systems, ensuring we can meet diverse client needs.

- Carbon Fiber

- Kevlar

- Fiberglass

- Paints – Primer / Top coats / Anti-static coatings

- Composite Tubes and Rods

Industries we offer custom composite manufacturing service

Elevate your products with our expert composite part production and prototyping services. Our team of engineers delivers unparalleled efficiency and support throughout your journey, from concept to final product. Solutions tailored to your unique needs.

- Aerospace and Defense

- Automative

- Marine

- Construction

- Sporting Goods

- Industrial Products

- Oil and Gas

- Medical

Composite Production Process

At OAK Engineering and Manufacturing, we leverage a diverse range of cutting-edge composite production processes to meet your unique needs. Our expertise spans various techniques, ensuring we can deliver the perfect solution for your project, whether it requires precision, scale, or complex geometries. Our advanced processes include:

Wet-Layup

A flexible, cost-effective manual process ideal for low-volume production and prototyping, though quality can vary.

Forging

A high-pressure, high-volume process delivering durable, consistent parts efficiently, often used in automotive and industrial applications.

Resin Infusion

A vacuum-driven method offering superior resin control for stronger, high-quality parts with minimal voids.

Prepeg

A precision process using pre-impregnated fibers cured under heat and pressure, producing the strongest, highest-quality parts, ideal for aerospace and performance sectors.

Our team of experts engineers are ready to help you

Get Your Custom Quote in 24 Hours

Reviewed by a real-life experienced engineers

Enter details, upload your file and specify your needs.

Get a custom quote in 24 hours.

Ideal for large orders or orders with special needs.

Contact an Engineer

Our Team of Engineers are ready to help you

Need a one-on-one engineer support

to get your part just right before manufacturing.

Contact Us Now!

Need Help Getting Your Parts Just Right?

Our team of first-hand engineers are committed to your part’s perfection.

Engineers dedicated to your project’s success, providing hands-on assistance and expert advice to ensure your custom parts are perfect from start to finish.

Our Process is what makes the difference

01

Understanding your projects

We start by thoroughly understanding your project’s requirements, ensuring we capture every detail to deliver the perfect part tailored to your specific needs.

02

Ensuring Manufacturability

We will review your designs thoroughly, ensuring every custom part is manufacturable, optimizing efficiency, and minimizing costly errors.

03

production

plan

We create a detailed production plan and timeline, outlining each step to ensure efficient, timely, and precise manufacturing of your custom parts.

04

Final part

production

We proceed with the final production, followed by careful packaging to ensure your parts arrive in perfect condition, ready for immediate use.

Discover the benefits of partnering with us

First-hand Experienced Engineers

Our team, composed of engineers who have been clients themselves, understands the challenges of prototyping and manufacturing. This experience enables us to offer personalized service and solutions that meet our clients' specific needs.

Reliability and Precision Everytime

Our commitment to unmatched precision and reliability builds trust with our clients. You can count on us to turn their ideas into reality, exactly as they envision, especially in sectors like aerospace where precision is crucial.

Advanced Technological Integration

OAK E&M leverages cutting-edge technology to enhance the precision of our products and enable complex designs that traditional methods can't achieve.

Customized Solutions

We excel at providing customized solutions tailored to each project's specific needs. Our ability to adapt and create unique solutions not only meets client expectations but also distinguishes us from competitors who only deliver the part or prototype you ask.

Rapid Project Execution

Our commitment to efficiency means we complete projects with high precision and speed. This quick execution is crucial for clients with tight deadlines, giving them a competitive edge in fast-paced markets.

Proactive Problem Solving

Our team's proactive approach helps us address potential issues before they become problems. This foresight smooths out project flow, reduces downtime, and leads to higher client satisfaction thanks to our attention to detail.

Value-Added Services For Your Projects

Post finishing services for all your composites parts and products

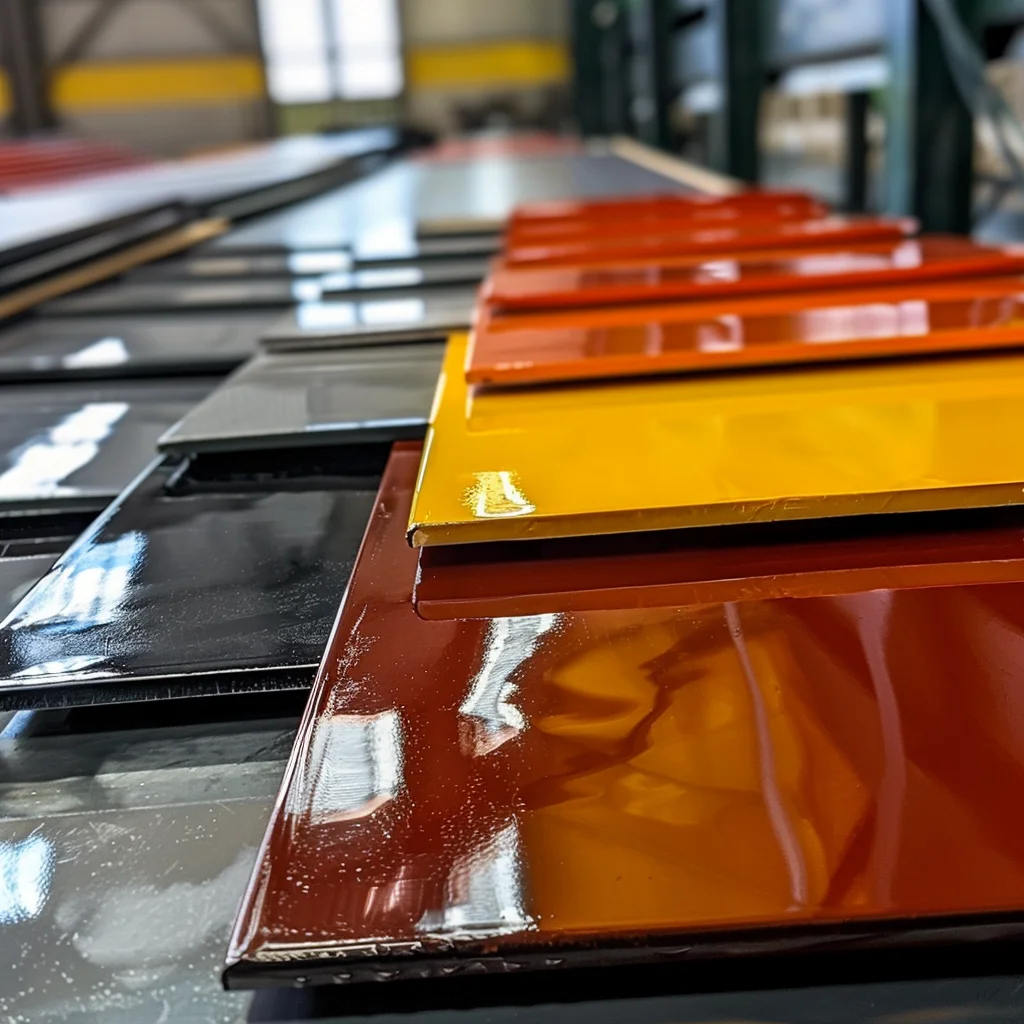

Molded Finish

Composites without any post process are just as strong as any other process. These parts come out with small imperfections or “pin holes” in the finish. For prototypes, internal parts, and cost-conscious parts this is perfectly acceptable.

Clear Coat

The next step up from the finish straight from the mold. Clear Coat or Gelcoat gives a smooth and glossy finish with minimal added weight. This is best if you want carbon weave to show through on the finished part.

Painted

We can paint in the mold for a semi-gloss finish that bonds directly with the epoxy for an exceptionally strong finish, or after the part has been pulled for a matte finish.

Trimming

We can manually or CNC trim the part for smooth edges, corners, holes, and for precise mating-part finishes.

FAQ

Our team is ready to help you with any question

What types of composite materials do you work with?

At OAK Engineering and Manufacturing, we work with a wide range of composite materials, including carbon fiber, fiberglass, aramid fibers, and various resin systems. Our expertise allows us to select the best materials for your specific project requirements.

Can you handle both small-scale prototypes and large production runs?

Absolutely! Our versatile facilities and experienced team enable us to manage projects of all sizes. Whether you need a single prototype or high-volume production, we have the capabilities to meet your needs efficiently and cost-effectively.

What industries do you typically serve with your composite part production?

We serve a diverse range of industries, including aerospace, automotive, marine, sports equipment, and industrial applications. Our expertise in composite manufacturing allows us to adapt to the unique requirements of various sectors.

How do you ensure the quality of your composite parts?

Quality is our top priority. We maintain strict quality control measures throughout the production process, including in-house material testing, advanced tracking systems for traceability, and rigorous inspections at every stage of manufacturing. We also adhere to industry-specific standards and certifications.

How long does it typically take to produce a custom composite part?

Production time varies depending on the complexity of the part, the chosen manufacturing process, and the production volume. For prototypes, we can often deliver in a matter of weeks. For larger production runs, we’ll provide a detailed timeline during the quoting process. Rest assured, we always strive to meet or exceed agreed-upon deadlines.

Can you assist with the design and engineering of composite parts?

Yes, we offer comprehensive design and engineering services. Our team of experienced engineers can help optimize your part design for composite manufacturing, suggest material improvements, and even assist with the entire product development process from concept to final production.

Starting a project and need helping getting your part just right?

Let’s talk, we are ready to help you get the perfect part.

Call Us: 352-448-8842