Unmanned Consulting Services

Expert Unmanned Consulting

from Industry Leaders

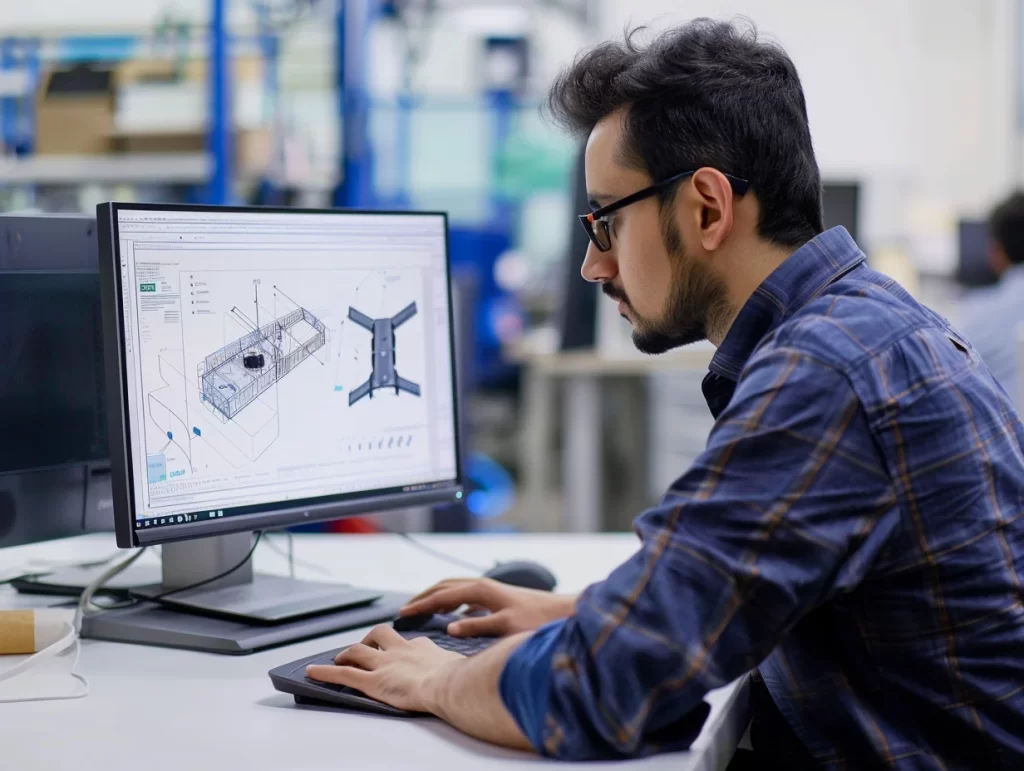

At Oak Engineering & Manufacturing, we partner with businesses to provide expert engineering and manufacturing solutions for your existing autonomous systems. From refining designs to solving complex production challenges, our specialized services ensure your unmanned technologies reach their full potential.

Need Expert Guidance in Unmanned Systems Integration?

Tailored Solutions for Your Unmanned Technology Needs

From strategic planning to hands-on implementation, our team of unmanned technology experts is ready to elevate your business. Let us help you navigate the complexities of autonomous systems and unlock new possibilities for growth

What Can We Do For You?

Unmanned System Integrations

At OAK Engineering and Manufacturing our expert consultation service helps you optimize your unmanned systems through seamless integration of cutting-edge technologies. We analyze your specific needs and design custom solutions that enhance performance, efficiency, and functionality. Our team’s deep knowledge of sensors, control systems, and composite materials ensures your unmanned platforms are perfectly tailored to your mission requirements.

Unmanned Vehicles Manufacturing

Leverage our advanced composite manufacturing capabilities to bring your unmanned vehicle designs to life. We specialize in producing high-performance UAVs, UGVs, and other autonomous platforms using state-of-the-art materials and techniques. Our precision engineering and quality control processes guarantee durable, lightweight vehicles that meet the most demanding operational standards. From prototyping to full-scale production, we’re your partner in creating next-generation unmanned vehicles.

Enhance Your Unmanned Vehicles Using Our Custom Composite Solutions

At OAK Engineering and Manufacturing, we pride ourselves on our versatile composite capabilities. Our state-of-the-art facility works with a wide array of fiber reinforcements and resin systems, ensuring we can meet diverse client needs.

We work with:

- Carbon Fiber

- Kevlar

- Fiberglass

- Paints – Primer / Top coats / Anti-static coatings

- Composite Tubes and Rods

Everything to build a complete composite UAV system

At OAK Engineering and Manufacturing, we’ve refined our composite production process to ensure efficiency without compromising quality. Our streamlined approach accelerates your product development cycle, getting your innovations to market faster. We integrate cutting-edge technology with our team’s extensive expertise to optimize every stage of production, from initial concept to final delivery.

Tooling and Mold Production

Our tooling and molding production phase sets the foundation for your composite part's success. We employ advanced CAD/CAM systems and CNC machining to create precise, durable molds that ensure consistency across production runs.

Prototyping, Testing and controls

Our comprehensive prototyping, testing, and control processes ensure your composite parts meet or exceed performance expectations before full-scale production begins.

Production and Post Finishing

Once your design is validated, we transition seamlessly into full-scale production. Our advanced manufacturing facilities and skilled technicians ensure consistent, high-quality output, whether you need a small batch or large production run.

Our team of experts engineers are ready to help you

Contact an Engineer

Our Team of Engineers are ready to help you

Need a one-on-one engineer support

to get your vehicle or part just right before manufacturing.

Contact Us Now!

Our Process is what makes the difference

01

Understanding your projects

We start by thoroughly understanding your project’s requirements, ensuring we capture every detail to deliver the perfect part tailored to your specific needs.

02

Ensuring Manufacturability

We will review your designs thoroughly, ensuring every custom part is manufacturable, optimizing efficiency, and minimizing costly errors.

03

production plan

We create a detailed production plan and timeline, outlining each step to ensure efficient, timely, and precise manufacturing of your custom parts.

04

Final part production

We proceed with the final production, followed by careful packaging to ensure your parts arrive in perfect condition, ready for immediate use.

Discover the benefits of partnering with us

First-hand Experienced Engineers

Our team, composed of engineers who have been clients themselves, understands the challenges of prototyping and manufacturing. This experience enables us to offer personalized service and solutions that meet our clients' specific needs.

Reliability and Precision Everytime

Our commitment to unmatched precision and reliability builds trust with our clients. You can count on us to turn their ideas into reality, exactly as they envision, especially in sectors like aerospace where precision is crucial.

Advanced Technological Integration

OAK E&M leverages cutting-edge technology to enhance the precision of our products and enable complex designs that traditional methods can't achieve.

Customized Solutions

We excel at providing customized solutions tailored to each project's specific needs. Our ability to adapt and create unique solutions not only meets client expectations but also distinguishes us from competitors who only deliver the part or prototype you ask.

Rapid Project Execution

Our commitment to efficiency means we complete projects with high precision and speed. This quick execution is crucial for clients with tight deadlines, giving them a competitive edge in fast-paced markets.

Proactive Problem Solving

Our team's proactive approach helps us address potential issues before they become problems. This foresight smooths out project flow, reduces downtime, and leads to higher client satisfaction thanks to our attention to detail.

FAQ

Our team is ready to help you with any question

What types of unmanned systems do you provide consultation for?

We offer consultation services for a wide range of unmanned systems, including aerial vehicles (UAVs), ground vehicles (UGVs), marine vehicles (USVs), and specialized robotic platforms.

How can your consultation services improve our existing unmanned systems?

Our experts analyze your current systems and recommend optimizations in areas such as sensor integration, control systems, materials use, and overall design to enhance performance, efficiency, and functionality.

Do you assist with regulatory compliance for unmanned systems?

Yes, we provide guidance on navigating the complex regulatory landscape for unmanned systems, ensuring your platforms meet all necessary certifications and operational requirements.

Can you help us choose the right sensors and payloads for our specific mission needs?

Absolutely. We assess your mission requirements and recommend the most suitable sensors and payloads, considering factors like weight, power consumption, data quality, and integration complexity.

What types of composite materials do you recommend for unmanned aerial vehicles (UAVs)?

For UAVs, we often recommend advanced composites such as carbon fiber reinforced polymers (CFRP) for their exceptional strength-to-weight ratio. We also consider specialized composites like aramid fibers for impact resistance or glass fiber composites for cost-effective solutions, depending on your specific requirements.

Can your consultation services help us reduce the operational costs of our unmanned fleet?

Yes, our consultations aim to optimize system efficiency, which can lead to reduced fuel consumption, lower maintenance requirements, and extended service life. We also advise on streamlining operations and implementing cost-effective technologies to minimize long-term expenses.

Starting a project and need helping getting your part just right?

Let’s talk, we are ready to help you get the perfect part.

Call Us: 352-448-8842